Maplan Rubber Injection Moulding

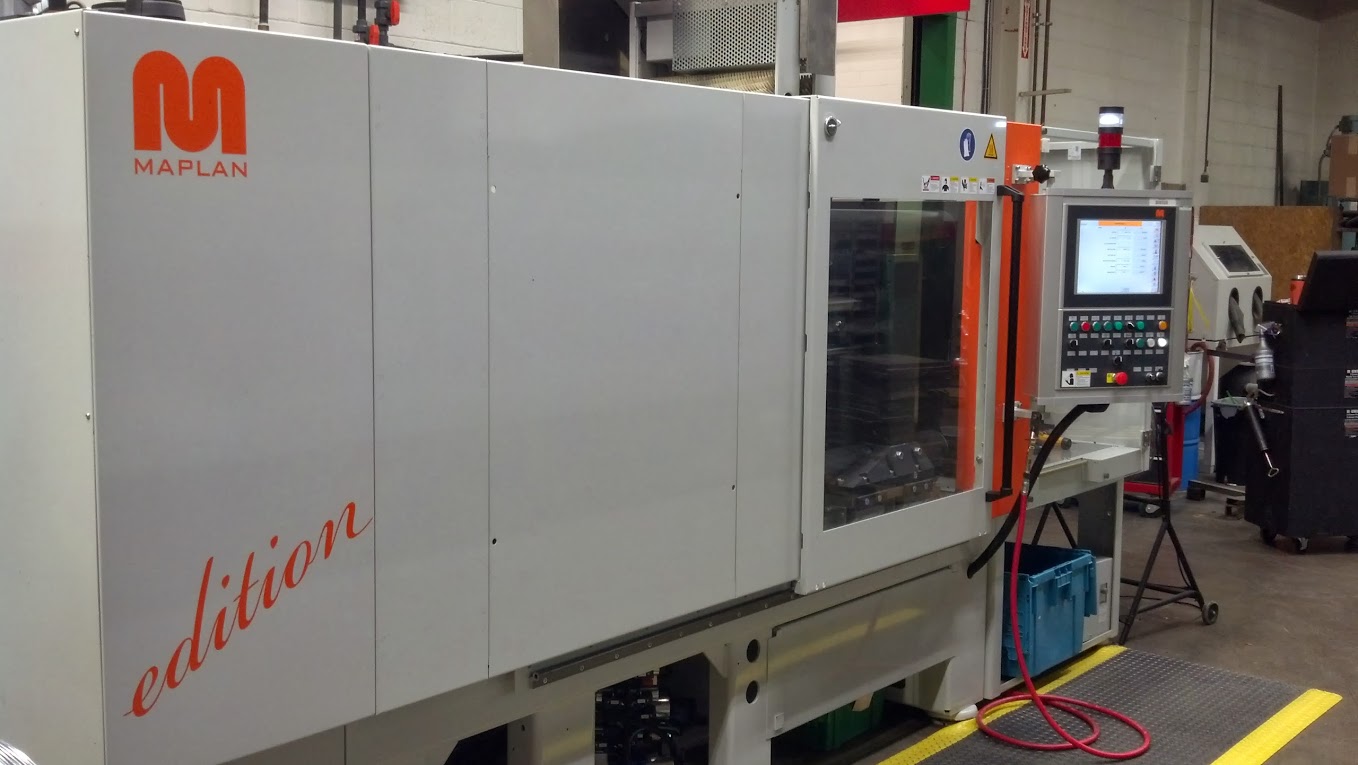

Via using appropriate peripheral equipments for instance shuttle systems it is possible to automate the extracting process of the rubber parts.

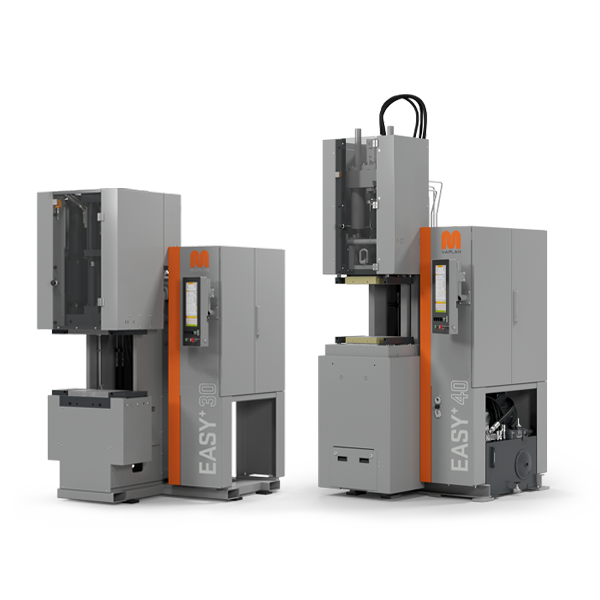

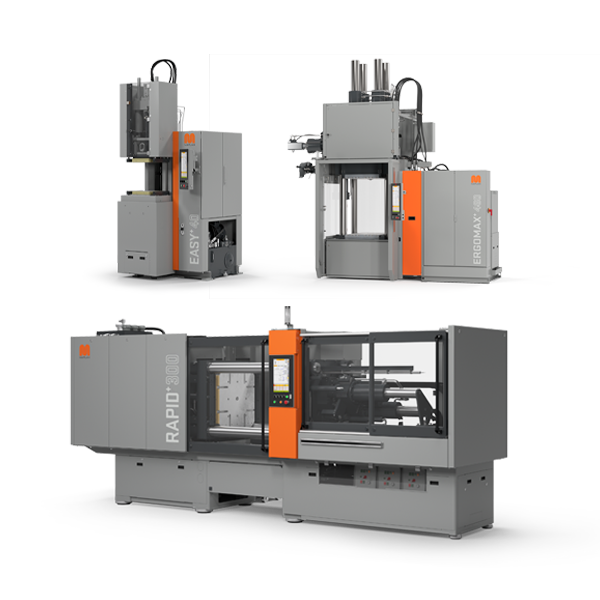

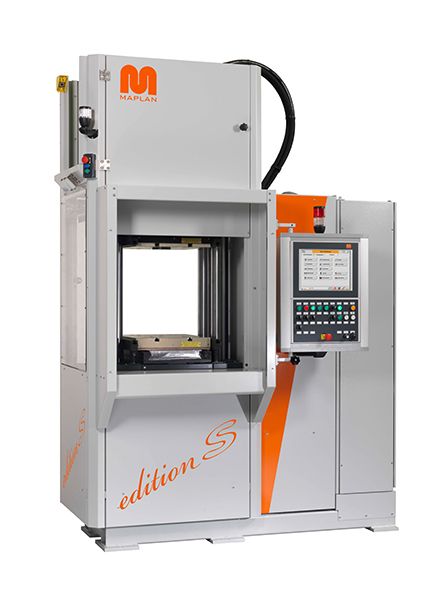

Maplan rubber injection moulding. Injection from above below or 2k dual compound specialised. The maplan vertical rubber injection moulding machines are qualified to produce all kinds of rubber mould types especially rubber combination parts like rubber metal parts. Decisive advantages lie in the brilliant simplicity of their structure and the performance and accuracy of the system. Maplan is a leading producer of elastomer injection moulding machines and an expert in 360 degree system solutions for the semi and fully automated production of rubber and silicone products.

The maplan fifo rubber injection unit allows an injection pressure of up. Maplan has stood for expertise and reliability since 1972. Vertical rubber injection moulding machines the maplan vertical machines are qualified to produce all kinds of rubber mould types especially rubber combination parts like rubber metal parts. Maplan has stood for expertise and reliability since 1970.

Maplan is a leading producer of elastomer injection moulding machines and an expert in 360 degree system solutions for the semi and fully automated production of rubber and silicone products. Can be enhanced with the addition of robotics automation solutions peripheral devices versatile. The maplan fifo rubber injection unit has been proven for many years and is still the unsurpassed component of maplan rubber injection moulding machines. The partnership with our customers is the base for common success.

Wide range with a variety of clamping and injection units available productive. If you would like to be a part of this please contact us or inform yourself by clicking through our website to access the worldwide marketing network of maplan special features of maplan. The advantages of maplan rubber injection moulding systems are in the technical details. Maplan a global player in technology.